Allocations Module-Allocating of material to Work Orders

New module in the ERP system – Priority to support the regulatory requirement to manage components through all l BOM levels up to the Finish Good.

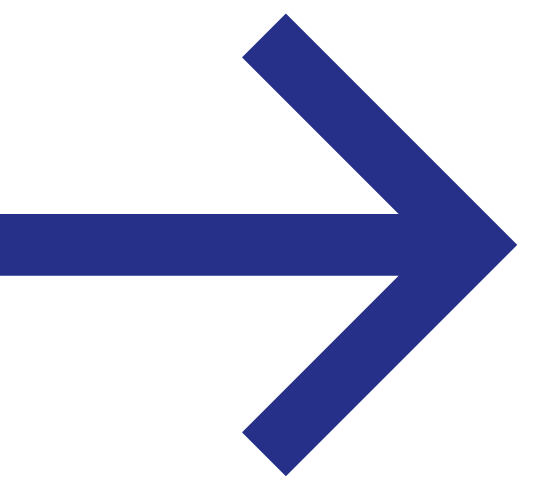

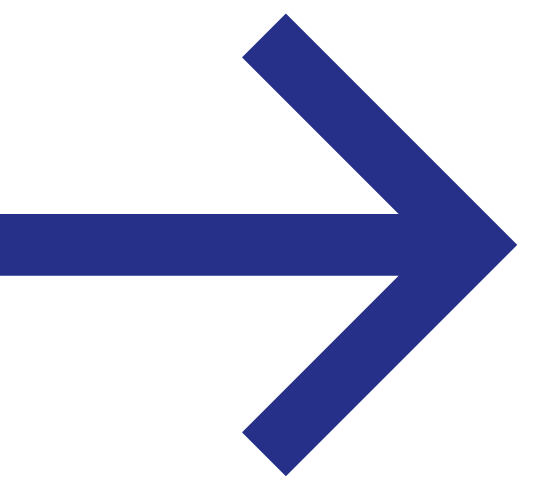

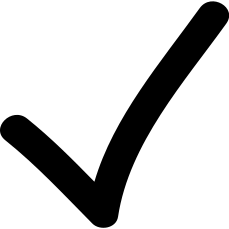

Material allocation module based on the dynamic activity of all logistical elements. (see picture below).

Material allocation module based on the dynamic activity of all logistical elements. (see picture below). Unlike all Operational ERP systems, material can be allocated already at its the Work Order stage.

Unlike all Operational ERP systems, material can be allocated already at its the Work Order stage. Related to Alternatives, combinations of components that affect the laboratory inspection time.

Related to Alternatives, combinations of components that affect the laboratory inspection time. Batches mixing limitation

Batches mixing limitation Expiry date, minimum time limit for delivery to the customer, etc.

Expiry date, minimum time limit for delivery to the customer, etc. Automatic opening of a work order by the system.

Automatic opening of a work order by the system. integrated with MRP recommendations.

integrated with MRP recommendations. Alerts , Inventory balance, Allocation balances.

Alerts , Inventory balance, Allocation balances. Work plan for Production department and Quality Assurance department.

Work plan for Production department and Quality Assurance department. Planning Expiration Dates.

Planning Expiration Dates.

BOM

Blending

Blending

MRP

recommendations

recommendations

WORK PLANS

Catalogue - Alternate Part

Lead Time

Lead Time

INVENTORY REP.

(WITH ALLOCATION)

(WITH ALLOCATION)

Transactions Audit

-Same History / Alloc Lots

-Labeled Limitation

-Same History / Alloc Lots

-Labeled Limitation

ISSUE ALLOCATIONS

Production

Production

Customers Limitations (expiry period limitation)

SHORTAGES REPORT

Inventory (expiry, WH status, Qty)

Bags

Bags

Work Orders & Batch Nbr.

ALLOCATIONS

Planning

Planning